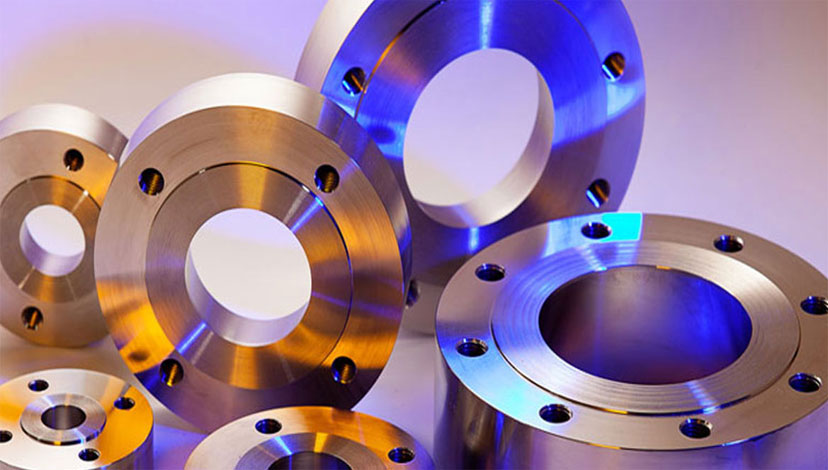

Forged Flanges

Micro Steel Corporation is distinguished Forged Flanges manufacturer, supplier & exporter.we offer high durable Forged Flanges in a variety of sizes and dimensions.Forged Flanges are manufactured using high grade metals such as Stainless Steel, Duplex,Carbon Steel, Alloy Steel , Nickel Based Alloys and Titanium.Metal Forgings that we offer have dimension standards such as ANSI / ASME B 16.5, B 16.1, B 16.47 series 'A' and 'B' , MSS SP-44, 10K, 16K, EN/DIN, JIS and BS 4504.we offer Forged Flanges in varied pressure ratings that range from 150 LBS to 2500 LBS.

Stainless Steel Flanges are basically rings or plates and it helps to connect piping components such as pipes, valves and other piping equipment to form a piping system with the use of bolted connections and gaskets.

We are specialist in Forged Flanges, Rings, Discs and special customized forgings can be availed as per drawing & requirement of clients.

| Stainless Steel | ASTM / ASME SA 182 F 304 / 304L / 304H / 316 / 316L / 316H / 309 / 309S / 310 / 310S / 317 , 317L , 321 , 321H , 347 , 347 H & 904L. |

| Duplex Steel | ASTM / ASME SA 182 F 44 , F 45 , F51 , F 53 , F 55 , F 60 , F 61. |

| Carbon Steel | ASTM / ASME A 105, ASTM / ASME A 350 LF 2. |

| Alloy Steel | ASTM / ASME A 182 GR F 5, F 9 , F 11 , F 12 , F 22 , F 91. |

| Nickel Alloy | ASTM / ASME SB 564 UNS 2200 ( NICKEL 200 ) , UNS 4400 (MONEL 400 ), UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 ( INCONEL 601 ) , UNS 6625 (INCONEL 625) , UNS 10276 ( HASTELLOY C 276 ), ASTM / ASME SB 160 UNS 2201 (NICKEL 201 ), ASTM / ASME SB 472 UNS 8020 ( ALLOY 20 / 20 CB 3 ). |

| Copper Alloy | ASTM / ASME SB 61 UNS NO. C 92200 & ASTM / ASME SB 62 UNS

NO. C 83600. ASTM / ASME SB 151 UNS NO. 70600 , 71500 , C 70600 ( CU -NI- 90/10) , C 71500 ( CU -NI- 70/30). ASTM / ASME SB 152 UNS NO C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200. |

Stainless Steel Flanges

Stainless Steel flanges are devices used to connect pipes, valves, pumps, and other equipment to form a piping system. They provide a method for easy assembly and disassembly of the piping system, as well as for access to the interior of the system for maintenance and repairs. Flanges can be made from various materials

These materials are chosen based on their compatibility with the fluid or gas being transported, their resistance to corrosion and high temperatures, and other factors specific to the application.

| Flanges Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, MSS SP-44, BS4504, BS 10, EN-1092, DIN, JIS (10K,16K) ,ASA, API-605, AWWA, GOST. |

| Most Common available ASME B16.5 Flanges size range |

1/2” NB To 48” NB /Custom size above as per drawing DN15 To DN1200 /Custom size above as per drawing |

| Standard Flanges ANSI B 16.5 Pressure Class | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS PN2.5, PN6, PN10, PN16, PN25, PN40, PN63 (PN64), PN100, PN160, PN250, PN320 till PN400. |

| Types of Flanges | Weld Neck Ring Flange (WNRF), Stainless Steel Flanges Slip-On Ring Flange (SORF), Stainless Steel Flanges Blind Ring Flange (BLRF), Stainless Steel Flanges Socket Weld Ring Flange (SWRF), Stainless Steel Flanges Threaded Ring Flange, Stainless Steel Flanges Lap Joint Ring Flange (LJRF), Stainless Steel Flanges Ring Type Joint Flange (RTJF), Stainless Steel Flanges |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large MaleFemale (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove. |

| Flange Dimensions | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, MSS SP-44, BS4504, BS 10, EN-1092, DIN, JIS (10K,16K) ,ASA, API-605, AWWA, GOST or as per custom drawings. |

| Specialized manufacturer of (Special Design) (Customized Drawing) | RTI Forged Flanges (Customized size till 120” / DN3000) Large Diameter Forged Flanges (Customized size till 120” / DN3000) Rings / Discs (Customized size till 120” / DN3000) Square and Rectangular Flanges |

| Surface Finish & Coating | Steel Machined Smooth Finish Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Production technique | Forged, Heat treated and machined |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Origin | Indian / West Europe / Japan / USA / Korean |

| Key markets and industries for Flanges | Bitumen upgraders. Heavy oil refineries. Nuclear power (mostly seamless). Petrochemicals and acids Gas ,Power Shipbuilding, Construction Metallurgy |

| Brand | MSC |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying

NACE MR0103, NACE MR0175 |

|

Weld Neck Ring Flange (WNRF)

Weld Neck Ring Flange is flanges that designed to be joined to a piping system by butt welding. This kind of flange include lots of specification. Weld Neck Ring Flange is expensive because of its long neck and cost of people for contact WN flange with pipeline or fitting but is preferred for high-stress applications. The necks, or hubs, transmits stresses to the pipeline. The gradual transition of thickness from the base of the hub to the wall thickness at the butt weld provides important reinforcement of the Weld Neck Ring Flange. The bore of Weld-Neck flange matches bore of the pipeline, reducing turbulence and erosion.

Weld Neck Ring Flange is flanges that designed to be joined to a piping system by butt welding. This kind offlange include lots of specification, Weld Neck Ring Flange is expensive because of its long neck and cost of people for contact WN flange with pipeline or fitting but is preferred for high stress applications. The necks, or hubs, transmits stresses to the pipeline.

The gradual transition of thickness from the base of the hub to the wall thickness at the butt weld provides important reinforcement of the Weld Neck Ring Flange. The bore of Weld-Neck Ring flange matches bore of the pipeline, reducing turbulen.

| Dimensions | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, MSS SP-44, BS4504, BS 10, EN-1092, DIN, JIS (10K,16K) ,ASA, API-605, AWWA, GOST |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Size | 1/2” NB To 48” NB /Custom size above as per drawing DN15 To DN1200 /Custom size above as per drawing |

| Class | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| DIN | DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673 DIN Standard ND-6,10, 16, 25, 40 Etc. |

| BS | BS4504 , BS4504, BS1560, BS10 , PN6 , PN10 , PN16 , PN25 , PN40, etc |

| Table | D / E / F / H / J / K |

| API STANDARDS | PSI-2000/3000/5000/10000/ETC |

| JIS Standards | 2220-2004 5k/10k/16k , ETC |

| Brand | MSC |

Slip-On Ring Flange (SORF)

Slip-On Ring Flange have bored with a diameter slightly larger than the pipe; this helps it to slide\slip over the pipe. This ANSI B16.5 SORF Flange is then welded inside and outside too, with fillet welding. Alloy Steel Slip-On Ring Flange are thinner compared to other ranges, cost-effective and are easy to use in fabricated applications. We supply Stainless Steel Slip-on Raised Face Flanges in both raised face and at faced designs, to industries like agricultural, fertilizers, pharmaceutical, textile and for general engineering purposes.

| Dimensions | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, MSS SP-44, BS4504, BS 10, EN-1092, DIN, JIS (10K,16K) ,ASA, API-605, AWWA, GOST |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Size | 1/2” NB To 48” NB /Custom size above as per drawing DN15 To DN1200 /Custom size above as per drawing |

| Class | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| DIN | DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673 DIN Standard ND-6,10, 16, 25, 40 Etc. |

| BS | BS4504 , BS4504, BS1560, BS10 , PN6 , PN10 , PN16 , PN25 , PN40, etc |

| Table | D / E / F / H / J / K |

| API STANDARDS | PSI-2000/3000/5000/10000/ETC |

| JIS Standards | 2220-2004 5k/10k/16k , ETC |

| Brand | MSC |

Blind Ring Flange (BLRF)

Commonly referred as blanking flanges, Blind pipe flanges are widely used in high pressure applications. Blind Ring Flanges are generally used to seal the end of a piping system to prevent flow of liquids or gases. The use of Blind Ring Flanges allows ease of access to a piping system once it has been closed. Our Blind Ring Flanges are available with raised or RTJ faces and also with female threads. Blind Ring Flanges can be supplied with or without hub as per the customer requirements. We offer blind plate flanges manufactured at our facility to companies in various industries including shipbuilding, power generation, petrochemical plants, oil refineries, waste water treatment plants, paper mills, pharmaceutical plants and turnkey projects among others.

| Dimensions | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, MSS SP-44, BS4504, BS 10, EN-1092, DIN, JIS (10K,16K) ,ASA, API-605, AWWA, GOST |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Size | 1/2” NB To 48” NB /Custom size above as per drawing DN15 To DN1200 /Custom size above as per drawing |

| Class | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| DIN | DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673 DIN Standard ND-6,10, 16, 25, 40 Etc. |

| BS | BS4504 , BS4504, BS1560, BS10 , PN6 , PN10 , PN16 , PN25 , PN40, etc |

| Table | D / E / F / H / J / K |

| API STANDARDS | PSI-2000/3000/5000/10000/ETC |

| JIS Standards | 2220-2004 5k/10k/16k , ETC |

| Brand | MSC |

Socket Weld Ring Flange (SWRF)

Socket Weld Ring Flange (SWRF) are counter-bored i.e. the bore of the Flange and pipe, both are same, thereby providing a good ow of the product through the pipe. Initially used for small-sized high-pressure pipes, our SMO 254 Socket Weld Ring Flange are now used in high-pressure systems too. Our Stainless Steel Socket Weld Ring Flange are oxidation resistant and promote better weldability and fabricability. We seek to offer ANSI B16.5 Carbon Steel Socket Weld Ring Flange that have excellent stress corrosion cracking resistance to the LNG, seawater and mining industry.

| Dimensions | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, MSS SP-44, BS4504, BS 10, EN-1092, DIN, JIS (10K,16K) ,ASA, API-605, AWWA, GOST |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Size | 1/2” NB To 48” NB /Custom size above as per drawing DN15 To DN1200 /Custom size above as per drawing |

| Class | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| DIN | DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673 DIN Standard ND-6,10, 16, 25, 40 Etc. |

| BS | BS4504 , BS4504, BS1560, BS10 , PN6 , PN10 , PN16 , PN25 , PN40, etc |

| Table | D / E / F / H / J / K |

| API STANDARDS | PSI-2000/3000/5000/10000/ETC |

| JIS Standards | 2220-2004 5k/10k/16k , ETC |

| Brand | MSC |

Threaded Ring Flange

The most noteworthy feature of these changes is that they can be joined to a pipe without welding. The bore of Nickel Threaded Ring Flange have threads and can be fitted to pipes that have external threads. Stainless Steel Threaded Ring Flange are low priced, t best for small pipes and can be used in low-pressure applications. They are very beneficial in highly combustible industries where welding is dangerous. We are certified to cater to the challenging requisites of a number of industries through our outstanding products and extraordinary services

| Dimensions | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, MSS SP-44, BS4504, BS 10, EN-1092, DIN, JIS (10K,16K) ,ASA, API-605, AWWA, GOST |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Size | 1/2” NB To 48” NB /Custom size above as per drawing DN15 To DN1200 /Custom size above as per drawing |

| Class | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| DIN | DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673 DIN Standard ND-6,10, 16, 25, 40 Etc. |

| BS | BS4504 , BS4504, BS1560, BS10 , PN6 , PN10 , PN16 , PN25 , PN40, etc |

| Table | D / E / F / H / J / K |

| API STANDARDS | PSI-2000/3000/5000/10000/ETC |

| JIS Standards | 2220-2004 5k/10k/16k , ETC |

| Brand | MSC |

Lap Joint Ring Flange (LJRF)

Lap Joint Ring Flange are used with a stub end, which is welded to the pipe. Alloy Steel Lapped Flanges are designed in a way that they swing over the pipe without the need to be welded. As they do not come in contact with the inner fluid, they do not corrode and can be re-used. Our ANSI B16.5 Stainless Steel Flanges are inexpensive and widely useful. In addition, they can be easily assembled and dismantled for a quick inspection

| Dimensions | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, MSS SP-44, BS4504, BS 10, EN-1092, DIN, JIS (10K,16K) ,ASA, API-605, AWWA, GOST |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Size | 1/2” NB To 48” NB /Custom size above as per drawing DN15 To DN1200 /Custom size above as per drawing |

| Class | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| DIN | DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673 DIN Standard ND-6,10, 16, 25, 40 Etc. |

| BS | BS4504 , BS4504, BS1560, BS10 , PN6 , PN10 , PN16 , PN25 , PN40, etc |

| Table | D / E / F / H / J / K |

| API STANDARDS | PSI-2000/3000/5000/10000/ETC |

| JIS Standards | 2220-2004 5k/10k/16k , ETC |

| Brand | MSC |

Ring Type Joint Flange (RTJF)

(RTJ) that are best-in-class. A Ring type joint flange(RTJ) is a machined metallic ring with a deep groove cut into its face. This groove rests a metal ring which gets compressed when the connecting bolts of the flange are tightened. This compression results in a leak-proof, close-fitting seal on the pipe or connection. Stainless Steel Ring type Joint Flanges are classically used in high-pressure and high-temperature services, while Carbon Steel Ring type Joint Flanges are spill-proof.

| Dimensions | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, MSS SP-44, BS4504, BS 10, EN-1092, DIN, JIS (10K,16K) ,ASA, API-605, AWWA, GOST |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Size | 1/2” NB To 48” NB /Custom size above as per drawing DN15 To DN1200 /Custom size above as per drawing |

| Class | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| DIN | DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673 DIN Standard ND-6,10, 16, 25, 40 Etc. |

| BS | BS4504 , BS4504, BS1560, BS10 , PN6 , PN10 , PN16 , PN25 , PN40, etc |

| Table | D / E / F / H / J / K |

| API STANDARDS | PSI-2000/3000/5000/10000/ETC |

| JIS Standards | 2220-2004 5k/10k/16k , ETC |

| Brand | MSC |